- +213 0 773 95 85 97

- info@oyaksmachines.com

TERTIARY IMPACT CRUSHER

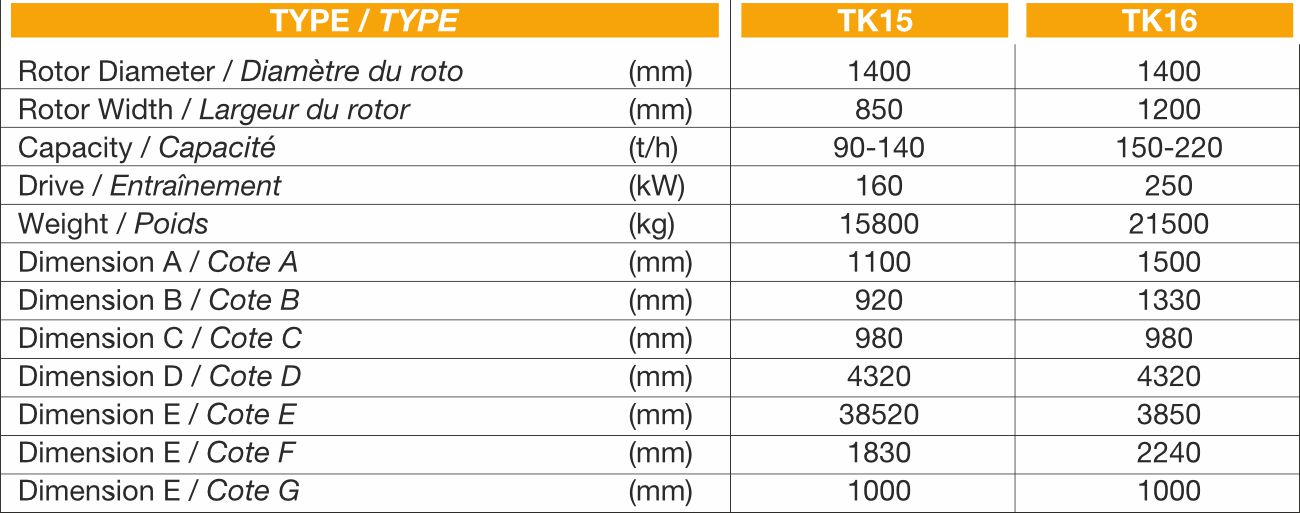

Kestasmak tertiary impact crushers are designed for crushing soft and medium hard materials in close and regular cubic shapes. These crushers are the perfect solution to obtain fine aggregates that are highly suitable for asphalt and concrete production. Adjustable and replaceable pendulums can break up to 50 percent fine product with a durable rotor that can work in both directions, which reduces the operating and inventory costs of the crusher.

Crusher Body

A special chamber design has been developed in order to increase the crushing capacity of the Kestasmak tertiary impact crushers . Thanks to this design , the product coming from the feeding system is distributed homogeneously.

Pendulum

Thanks to its independent three pendulum system , it provides high efficiency gradation control. lts upper and lower pendulums are hydraulically controlled and have a jamming safety system. Lower pendulums offer grinding flexibility and capacity.

Wear Parts

lmproved durable wear parts and linings.

Rotor

Kestasmak tertiary impact crushers have G 6.3 precision dynamically balanced rotor quality according to ISO 1940/1. The flywheel and pulley system , which is connected to the shaft with tightening collars , provides long-term use.

Bearings

Heavy-duty high quality SKF bearings and bearing temperature sensors.

Double Sided Rotation

The rotors in our impact crushers can work on both sides. This way, when the wear parts on one side of the breaker wear out , operators can change the rotor’s running direction to the other. This method allows customers to reduce their inventory costs by reducing the maintenance period and the cost of parts.

You can call our support team at +213 0 773 95 85 97.

Sarl Oyaks Machines

Dadash Importation Exportation

Machines

Spare Parts

Project

About Us

© 2024 All rights reserved